Explore the Key Cement Plant Manufacturers for Fuelling Growth

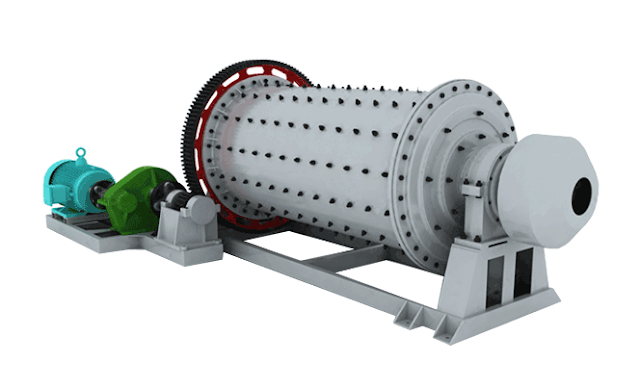

The global construction industry thrives on a strong foundation – literally. Cement, the essential building block, fuels this growth, and behind every bag of cement stands a complex network of machinery and expertise. This is where cement plant manufacturers like CPG come in, playing a crucial role in shaping the future of infrastructure development. Chanderpur Group, with over six decades of experience, has established itself as a leading name among cement plant manufacturers in India. Our journey began in 1962 with a vision to empower infrastructure projects across the nation. Over the years, we have successfully supplied and commissioned over 400 cement plants, leaving a lasting mark on the landscape of the industry. Unveiling the Powerhouse of Cement Production We offer a robust portfolio of equipment specifically designed for cement production. Our state-of-the-art machinery includes: Ball Mills: Workhorses g...

%20(1).png)

.jpg)