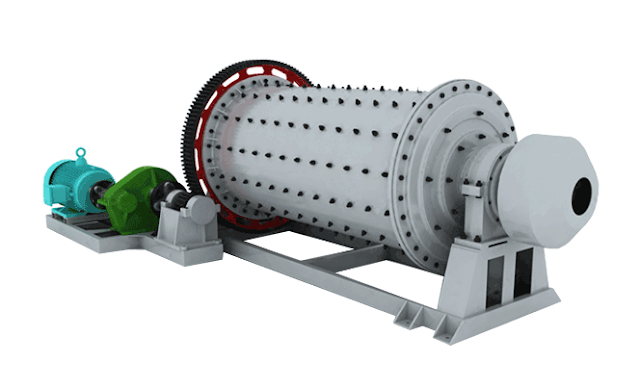

Improvements in Chromium Beneficiation Process using Ball Mills

Chromium has widespread uses in many industries, the primary use being the production of steel and other alloys. The industry equipment is largely dependent on steel for designing machines, therefore, the demand for chromium is always high in the market. The process of Chromite ball mill beneficiation has many bottlenecks and needs refining with optimization of techniques. When used in combination with ball mill for grinding, the main challenges faced in chromium beneficiation are discussed below:

· Difficulty in Separating

Chromium ores are usually found in igneous rocks and are mixed with many other minerals. The siliceous ores are rich in alumina alongside chromium while ferruginous contain iron. The problem with this arrangement is the separation by crushing and grinding. The process usually requires extra steps after crushing such as gravity separation to isolate chromium. This adds to the cost of beneficiation. Also, impurities are not always successfully removed in which case the capital invested is being spent on products with no value to the customer. It is possible to make improvements on this front.

Power Consumption

Production fine chromium particles are a challenging task. Ball mill is successfully utilized for conducting milling which is normally done in two steps: primary and secondary crushing. However, producing particles below 75 microns size can be more expensive. The process uses more power than intended and adds to the production cost. An estimation of the study reported nearly 30% more consumption of energy for generating ultrafine particles of chromium using a ball mill. A cheaper solution for this is required.

Ultrafine Particles

The

demand for ultrafine particles is considerable in the industry, however, their

production can be a difficult process. The majority of particles generated

using a ball mill lie in more than 45 microns range which is not considered ultrafine.

The technique when tweaked to increase production leads to more consumption of

power and loss of particles during the process. Nearly 30% of ultrafine particles

can be produced at nominal inputs.

Power Consumption

The

ball mill consumes about 30% of power during the entire process of chromium

beneficiation, however, this consumption increases when the production of ultrafine

particles is targeted. However, the returns from using more power are also not

promising. So, power can be a huge input if the product requires more particles in

finer proportion.

Type of Grinding

The technique needs optimization for dry grinding. In general, milling of chromium

is better when wet grinding methods are applied. The production of slurry

during wet grinding adds to the effectiveness of the milling making the process more

efficient. Due to this, the wet milling process is widely used, however, this

results in an increase in the production cost. The product needs to be

subjected to various treatments and drying methods to remove water.

Feed Rate and Mill Speed

Many

studies are being conducted which use variable parameters especially feed rate

and milling speed to determine whether these factors can be modified to achieve

higher efficiency in chromium processing. Although no definite answers have

been found. However, it is evident that regulation of these factors in ball mills

can yield promising results.

Conclusion

Ball mills

for chromium beneficiation are serving as an efficient means to an end,

however, better results are yet to be achieved. In general, ball mills have an

excellent application for chromium beneficiation presently with a promise to

achieve higher returns in the future.

Comments

Post a Comment